Production of Precision Tools, Molds, and Components for Plastic Injection Molding and Processing of PU and Rubber Parts

We specialize in the design, development, and manufacturing of high-precision tools, molds, and technological components intended for processing plastics, polyurethanes, and rubber compounds. We utilize modern machining technologies and high-quality materials to ensure long service life, reliability, and dimensional accuracy of our products, even in demanding production cycles.

We offer our customers complete solutions under one roof – from design and programming to assembly and final surface treatment. We manufacture molds and tools from both standard and special tool steels, tailored to the specific application and the properties of the injected or molded material.

Comprehensive Mold and Tool Manufacturing Process Includes

Mold Design and 3D Modeling

Processing of technical specifications and creation of a 3D mold model in .STP format, including functional and structural details.

Design optimization with respect to material properties, plastic shrinkage, cooling, venting, and mold durability.

Consultation with production already in the design phase to ensure manufacturability and efficient mold maintenance.

Technology Selection and CAD/CAM Programming

Use of modern CAD/CAM software for precise toolpath generation, including machining simulation.

Selection of the most suitable manufacturing strategy – from roughing to final finishing.

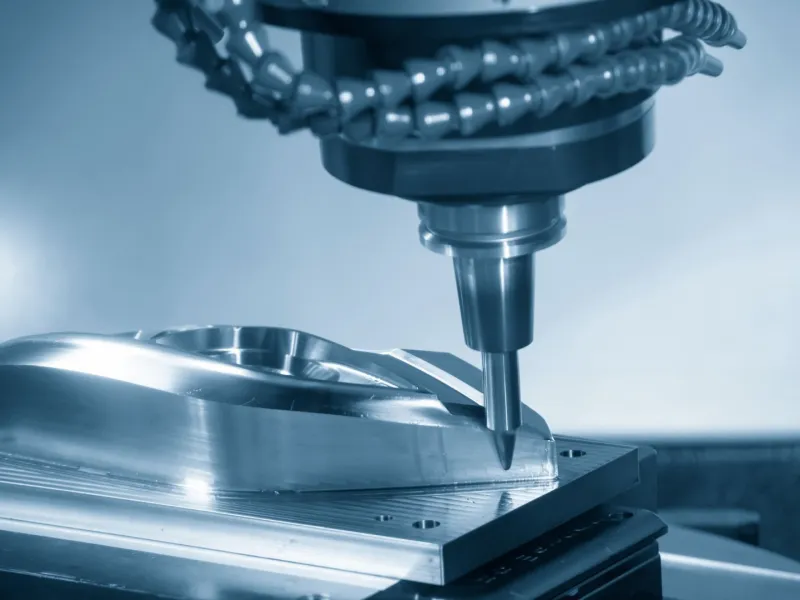

Preparation of programs for 3-axis and 5-axis CNC machining centers.

CNC Machining of Individual Components

Machining of mold inserts, cooling channel systems, guides, and complex 3D surfaces with high precision.

Processing of both small and large mold components with an emphasis on repeatability and dimensional stability.

Machining of standard and tool steels, hardened materials, and special alloys.

Mold Assembly and Toolmaking

Complete mold assembly including fitting of individual parts, functional testing of mechanisms and moving components.

Manual adjustments, fitting, functional testing, and mold try-outs before deployment in serial production.

Delivery of molds at various stages of completion (e.g., pre-assembled, fully assembled, with documentation).

Surface Finalization

Polishing, grinding, and manual finishing of mold functional surfaces according to required surface quality (matte, glossy, mirror finish, or texturing).

Surface preparation for molds intended for laminating or high-aesthetic pressing applications.

Option to apply technical surface treatments (e.g., nitriding, PVD coatings, chrome plating) as per customer specifications.

Production of Parts and Components for:

Injection molds for plastic packaging (thin-walled and technical moldings)

Molds for PU and rubber parts (seals, damping elements, fillers)

Core and cavity inserts, spacers, guides, interchangeable segments

Special tool assemblies for custom-built (single-purpose) machines

Precision. Durability. Efficiency.

Every tool and mold we produce undergoes strict final inspection, measurement, and testing. Our goal is to deliver a solution that ensures stable and trouble-free operation, even under demanding production conditions. We are ready to respond flexibly to individual requirements – from one-time projects to long-term serial production partnerships.

Entrust us with the development and manufacturing of your mold – from concept to the final molded part.

Contact us – we’ll be happy to propose a technical solution tailored to your project.