Technological readiness and manufacturing flexibility

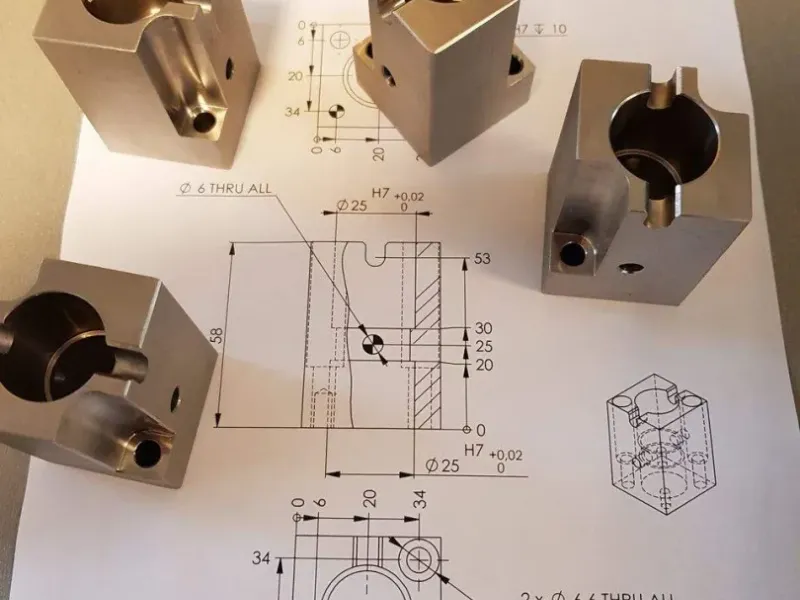

Our company is equipped to respond to a wide range of customer requirements in metal fabrication – from single-piece production and small batch orders to stable serial production. Projects are executed based on provided technical drawings, physical samples, or, if needed, a comprehensive technical documentation design prepared by our in-house engineering department.

This approach enables us to:

Optimize the production process and minimize costs from the initial phase,

Design structures with a focus on manufacturability and stability,

Prevent assembly errors and enhance the overall functionality and durability of the product.

Thanks to close collaboration between our technical and production teams, we can flexibly respond to specific technical demands and deliver complex structural assemblies that meet stringent standards across engineering, energy, automation, logistics, and other industrial sectors.

Modern machine equipment and production capacities

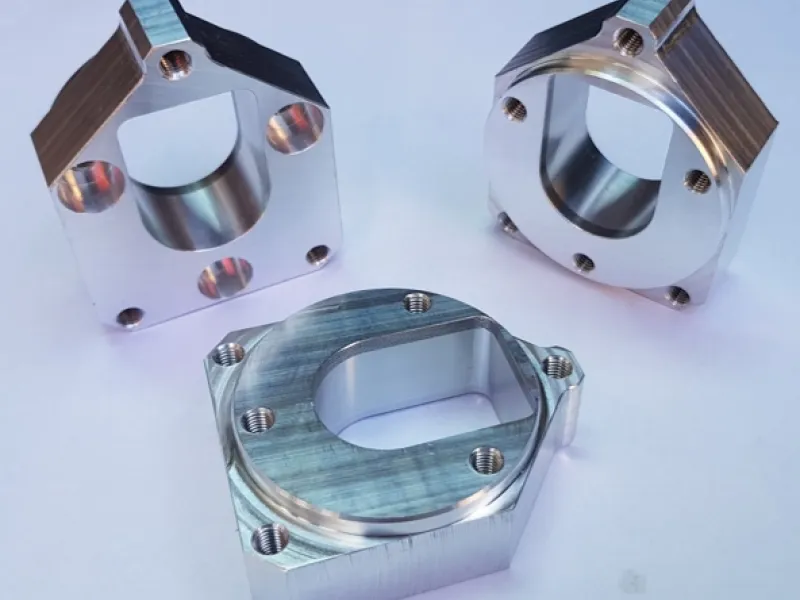

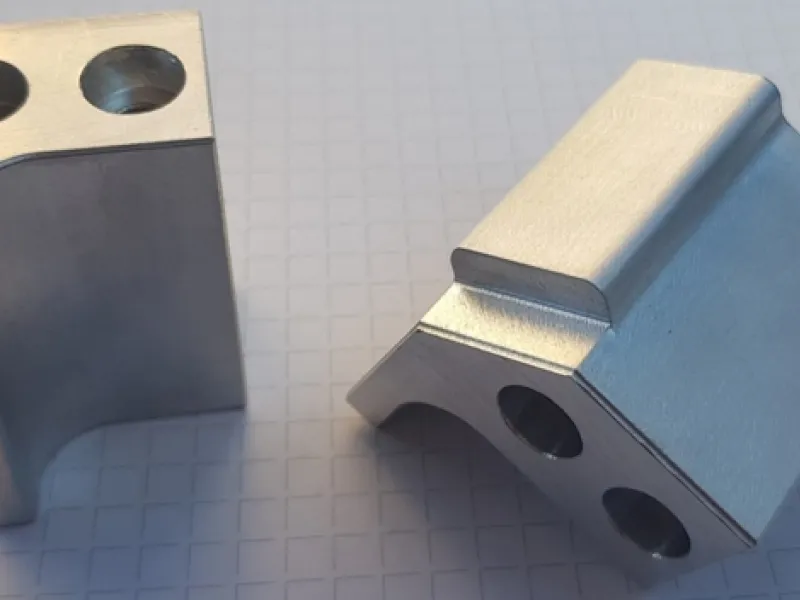

Our technological infrastructure allows us to machine a wide range of materials — from common carbon steel to stainless and tool steels, as well as special alloys. By combining modern CNC technologies with qualified personnel, we achieve high precision, repeatability, and production flexibility.

1. 3-axis and 5-axis CNC machining

- Enables precise milling of complex 3D shapes and spatial components requiring accurate coordination of tool movements across multiple axes.

2. Horizontal machining of oversized components and weldments

Suitable for large parts that demand high precision in machining contact surfaces, assembly points, and technical openings.

3. CNC turning and trapezoidal thread manufacturing

Ensures machining of rotating parts — from simple shafts to complex components with threads, including the production of special trapezoidal profiles for drive systems.

4. Grinding, polishing, and surface finishing

Focused on achieving the required surface roughness, aesthetic appearance, and functional condition with regard to the final use of the part.

5. Wire cutting – Electrical Discharge Machining (EDM)

Precise shaping of metal components with extremely tight tolerances and without thermal impact on the surrounding area — ideal for manufacturing accurate molds and contours.

Integrated manufacturing process – from design to assembly

In addition to machining, we have extensive welding and assembly capacities, allowing us to provide comprehensive turnkey solutions. Within a single production line, we can ensure:

Completion of weldments with guaranteed weld quality (ISO 3834-2),

Mechanical machining of functional surfaces after welding,

Final assembly of components, including hydraulic, pneumatic, and electrical subsystems,

Final quality inspection, measurement, documentation, and packaging.

This integrated manufacturing approach significantly reduces production lead times and eliminates risks associated with outsourcing or additional processing of components by third parties.

Benefits for the customer

Ability to complete the entire project under one roof – from design to assembly

Guaranteed manufacturability already at the design stage

Certified production quality and inspection according to international standards

Flexible production scheduling and quick response to changes

Cost savings and minimized downtime in the logistics and production chain

Your vision. Our technology. A shared solution.

We are ready to become your reliable partner in bringing your manufacturing projects to life — whether it’s a unique prototype, a special custom order, or stable serial production.

Contact us, and we will be happy to prepare a personalized offer tailored to your technical and production requirements.