Comprehensive Solutions for Conveyors and Material Handling

PWe offer the design, development, and production of conveyor systems tailored to various material types and production conditions. Thanks to our in-house design, manufacturing capacity, and experience in automation, we can deliver custom solutions that precisely meet the requirements of your specific application – from simple transport sections to complex integrated lines.

We handle the entire process: selecting the appropriate technology, optimizing material flow, designing and manufacturing individual components or complete assemblies, including control systems and sensors.

Our Conveyor Systems Are Designed For:

Material and Product Sorting

intelligent conveyor systems with sensor-based identification

sorting by weight, size, shape, or code

ideal for sorting lines in industry, logistics, and recycling

Transport and Dosing

precision conveyors and feeders for continuous or batch feeding of raw materials and parts into the next production stage

optional integration of weighing, dosing, or cutting modules

Conveyor System Automation

design and implementation of complex conveyor lines with automated control

integration of position, speed, and quantity sensors

streamlining and accelerating production flow while reducing manual handling requirements

Prototyping and Development

development of custom conveyor solutions based on specific customer requirements

functional prototype testing before deployment into serial production

flexible adjustments and optimization based on operational trials

Technological Options and Configurations

Belt, chain, roller, and modular conveyors for bulk materials, discrete products, pallets, and crates

Steel, aluminum, or stainless-steel construction, based on environment (dry, wet, hygienic, chemically aggressive)

Manual, semi-automatic, or fully automated systems

Optional integration of pneumatic, electric, or hydraulic drives, PLC control systems, and connection to existing lines

Why Work With Us

✔ Complete design and manufacturing under one roof

✔ Custom solutions based on material type and production requirements

✔ Years of experience in industrial automation and material handling

✔ Service, technical support, and fast adjustments throughout the system’s lifecycle

✔ Capability to deliver both prototypes and fully functional production lines

Smooth Material Flow. Stable Production Performance.

Get a reliable and efficient conveyor solution designed specifically for your production process.

Contact us – we’ll be happy to discuss your technical needs and propose a tailored solution.

Steel Conveyors with Metal Belts

Steel conveyors with metal belts are designed for heavy-duty industrial applications where standard rubber or plastic belts are insufficient. These conveyors provide a reliable solution for environments with high temperatures, sharp-edged materials, abrasive dust, or oil contamination.

Thanks to the fully metal belt construction—made from steel links, plates, or wire segments—our conveyors offer high resistance to mechanical damage, deformation, and wear, even during long-term, continuous operation.

Applications and Benefits

Waste Management and Recycling

transport of metal scrap, chips, sharp material remnants, and plastics with sharp edges

can be integrated with pressing and sorting systems

Metalworking Industry

suitable for chip removal from machining centers, lathes, and milling lines

capable of discharging materials into containers or storage bins

Foundries and Metallurgy

transportation of hot castings, sand, or glowing residues

resistant to high temperatures and thermal shock

Automated Production Lines

transport of heavier parts requiring a solid, stable base

optional features: lifting, sorting, diverting

Robust Solutions. Movement That Lasts.

We design and deliver steel conveyors built to withstand even the most demanding industrial conditions.

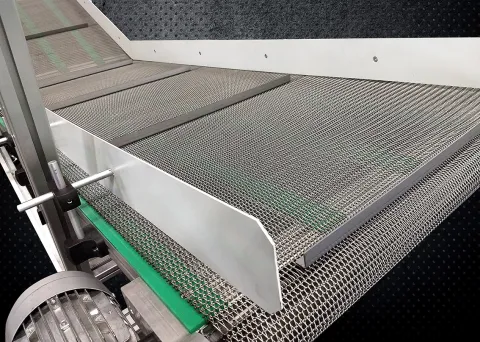

Steel Conveyors with Wire Mesh Belts

Steel conveyors with wire mesh belts offer an efficient solution for transporting products in environments with high temperatures, humidity, aggressive conditions, or stringent hygiene and cleaning requirements. Thanks to the open construction of the wire mesh, these conveyors allow for effective airflow, water drainage, or heat transfer—making them ideal for processes such as drying, washing, cooling, baking, or liquid removal.

We manufacture wire belts from high-quality carbon steel or stainless steel, depending on the operating conditions, with a focus on durability, stability, and easy maintenance.

Typical Applications and Industries

Food Industry

cooling or baking of products in tunnel ovens and cooling lines

transport of raw materials or finished foods in hygienic environments

suitable for washing, drying, and sterilization processes

Foundries and Heat Treatment Facilities

transport of hot parts, castings, or molded products during hardening, annealing, or tempering

excellent resistance to temperatures above 500 °C (when using stainless steel materials)

Machinery and Electronics Industry

drying after degreasing, chemical cleaning, or powder coating

part transport in automated processing lines

Plastic and Rubber Parts

draining of excess liquids and cooling of products after injection molding or pressing

Smooth Operation, Even in Extreme Conditions

We deliver custom-designed wire mesh conveyors tailored to your exact process requirements – from design and manufacturing to installation and service.

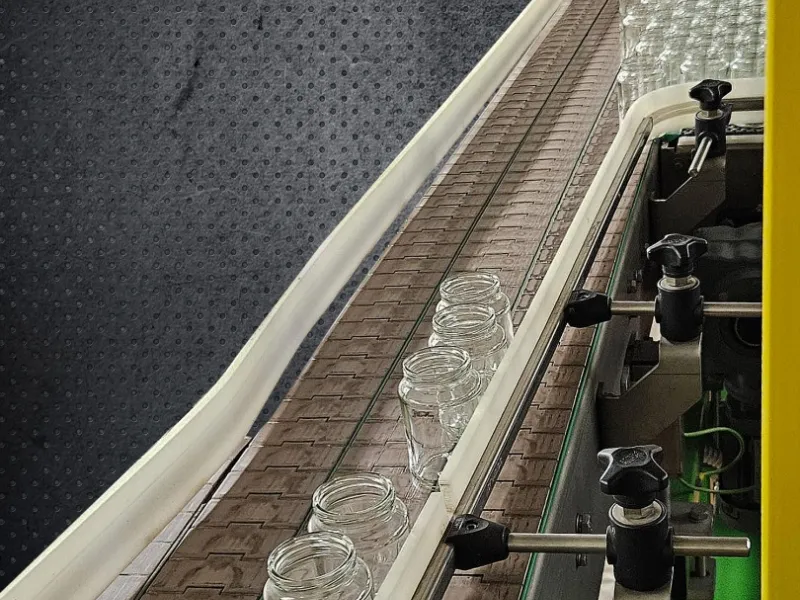

Handling Conveyors with Aluminum or Steel Structures

We offer the design, production, and installation of handling conveyors intended for the smooth movement of components, parts, containers, and finished products within manufacturing and logistics processes. We use modular aluminum and steel structural systems that allow for customization of the conveyor's shape, size, and functionality—tailored to the product type, operational requirements, and available space.

Handling conveyors are an ideal solution for connecting workstations, ensuring inter-operational flow, ergonomic part delivery to assembly stations, or feeding production lines via logistics paths.

Types of Handling Conveyors

Belt Conveyors – with PVC, PU, or textile belts; available with various surface finishes depending on the product type (smooth, ribbed, antistatic)

Roller Conveyors – both gravity and powered versions (motorized rollers, chain drives)

Feeding and Discharge Conveyors – for assembly lines, warehouse routes, scrap or part collection

Indexed Conveyors – with precise positioning for automated assembly, visual inspection, or robotic cells

Flexible Movement. A Solution That Adapts.

Get a reliable handling conveyor designed to perfectly suit your production requirements.