Production of Inspection and Measuring Fixtures – Precision, Repeatability, Efficiency

We specialize in the development and production of inspection, measuring, and technological fixtures for a wide range of industrial applications. Our solutions are individually designed – based on the specific purpose of use, required accuracy, ergonomics, control method, and production environment.

We manufacture everything from simple inspection templates to complex systems with pneumatic actuation, sensors, and integrated controls. Our designs focus on ease of use, repeatable measurement results, and optimization of the manufacturing process.

Types of Fixtures and Their Applications

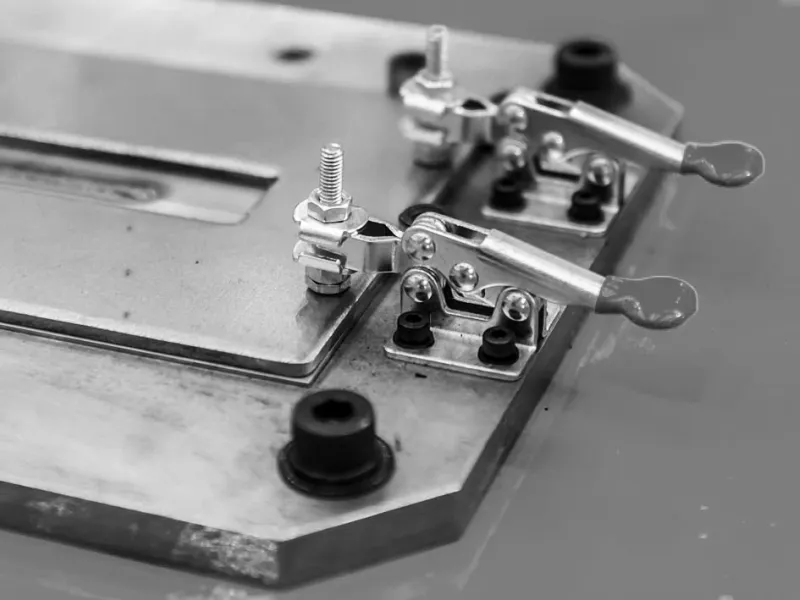

1. Inspection Fixtures (GO/NOGO / OK/NOK)

Designed for fast and reliable verification of shape accuracy and dimensional tolerances of finished parts

Used primarily in serial production for visual and functional checks without the need for measuring instruments

Option to integrate stops, positioning pins, sliding segments, or mechanical/electronic evaluation systems

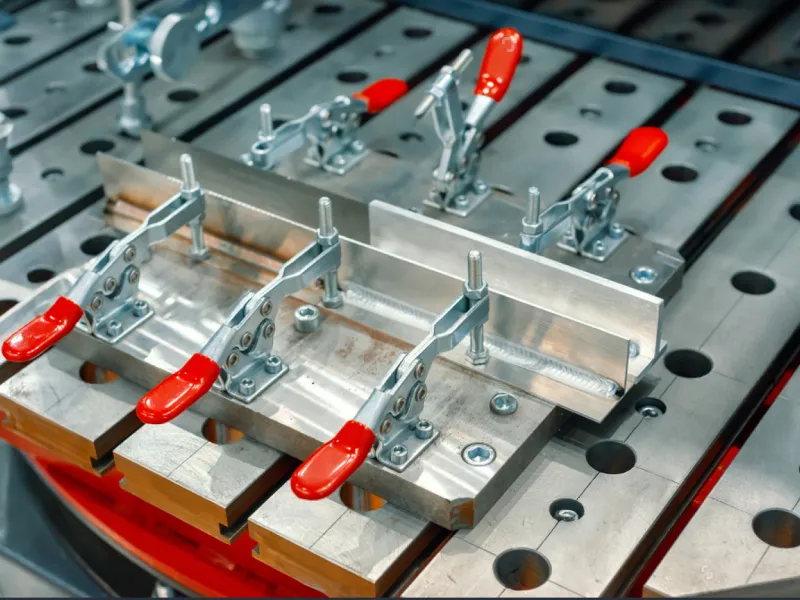

2. Clamping and Positioning Fixtures

Serve for accurate positioning and securing of parts during further processing (milling, drilling, machining)

Ensure repeatable and stable positioning without the need for measuring or manual adjustments

Reduce production setup time and increase operator safety

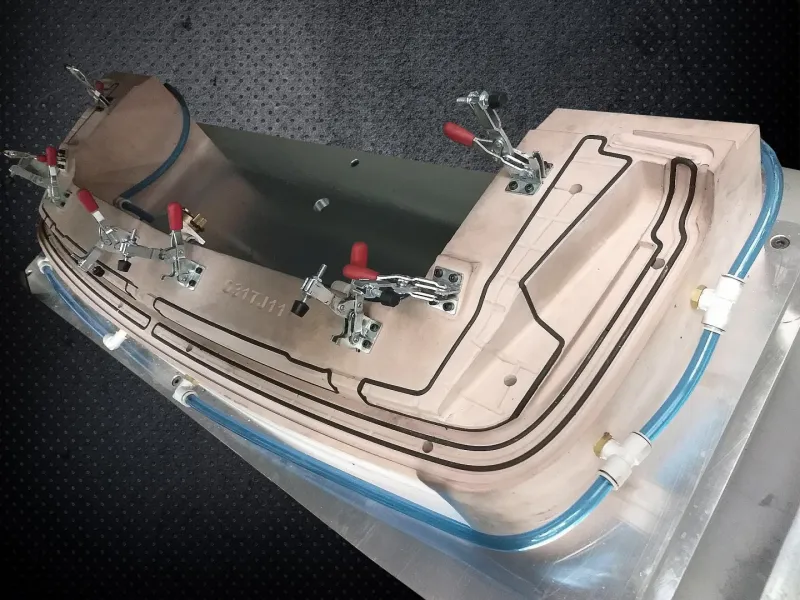

3. Bonding, Welding, and Assembly Fixtures

Designed for precise guiding and positioning of components before fixation

Option to integrate pneumatic elements for clamping and part release, as well as control and safety features

Ideal for repetitive, precise, and efficient assembly or for fixation during longer curing or bonding processes

Technical Execution and Build Options

Simple templates and manual fixtures made from engineering plastics, aluminum alloys (duralumin), or steel

Precision inspection fixtures with adjustable and interchangeable elements

Combined fixtures with mechanical or pneumatic modules for automated workstations

Optional integration of measurement systems, sensors, laser markers, or identification systems

Our Capabilities Include

In-house design and 3D modeling in CAD systems (with outputs in .stp, .igs, .dwg formats)

CAM programming for part production on 3-axis and 5-axis CNC machines

Precision machining, assembly, and final fine-tuning

Functional testing of fixtures directly at the customer's site or during trial operation

Delivery of technical documentation, user manuals, and inspection reports

Benefits of Working With Us

✔ Fixtures tailored to your specific process or product

✔ Quick modification or redesign options in case of product changes

✔ Reduced production cycle time and improved output quality

✔ Durable, ergonomic, and user-friendly solutions

✔ Expert consultation and technical support even after delivery

Precision in Every Detail. Reliability in Every Process.

Entrust your fixture production to an experienced team with strong technical background.

We’ll help you automate, streamline, and accelerate your production – from concept to delivery.

Contact us – we’ll be happy to discuss a tailored technical solution for your needs.