Comprehensive Surface Treatment Solutions – Cleaning, Protection, and Final Finishing of Components

As part of our complete metal part and structure deliveries, we provide professional surface treatment services that ensure long-term durability, corrosion protection, and a high-quality appearance of the finished products. We apply various technologies based on the material, intended use, and customer requirements – from mechanical cleaning to final surface coatings.

Our advantage lies in integrating the surface treatment process directly into the production workflow – without the need for external subcontractors – significantly reducing lead times and overall customer costs.

Our Surface Treatment Technologies Include:

Abrasive Blasting (Sandblasting) of Metal Surfaces

Mechanical cleaning using blasting media provides:

Complete removal of rust, scale, old coatings, and grease

Surface texture unification before applying further layers (e.g. zinc coating, painting)

Improved adhesion of protective coatings to the base material

Suitable for steel structures, weldments, and complex-shaped components.

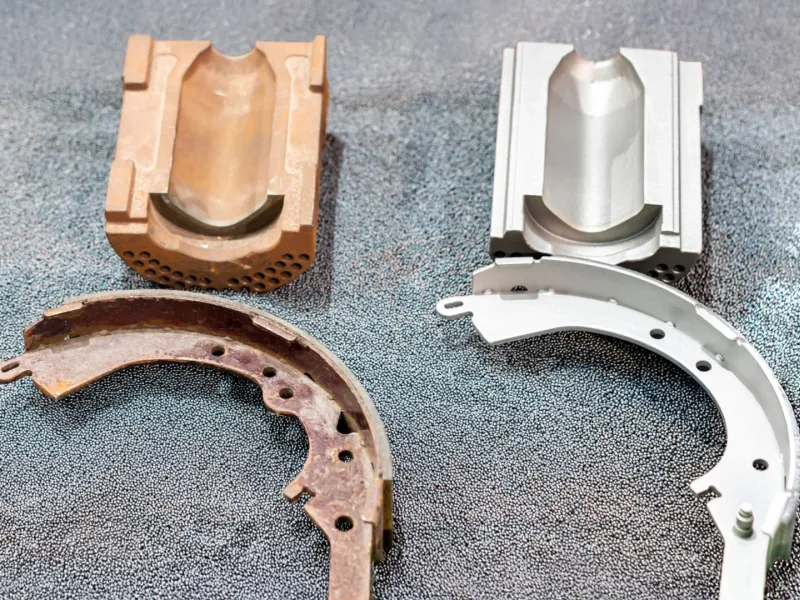

Electro-Galvanizing (Zinc Coating)

Application of a protective zinc layer via electrochemical process:

Long-term corrosion resistance even in demanding environments

Uniform and durable coating ideal for fasteners and functional parts

Perfect for components requiring high resistance to humidity and weather conditions

Performed in accordance with relevant industry standards.

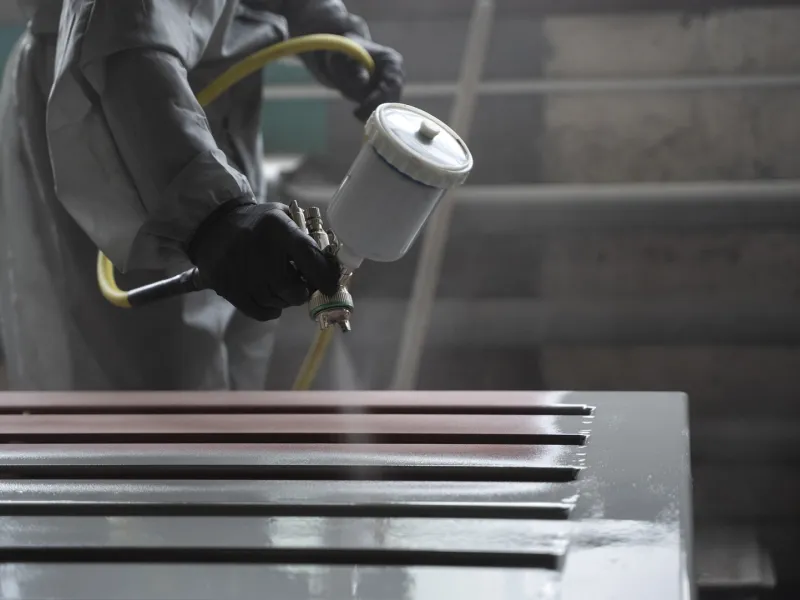

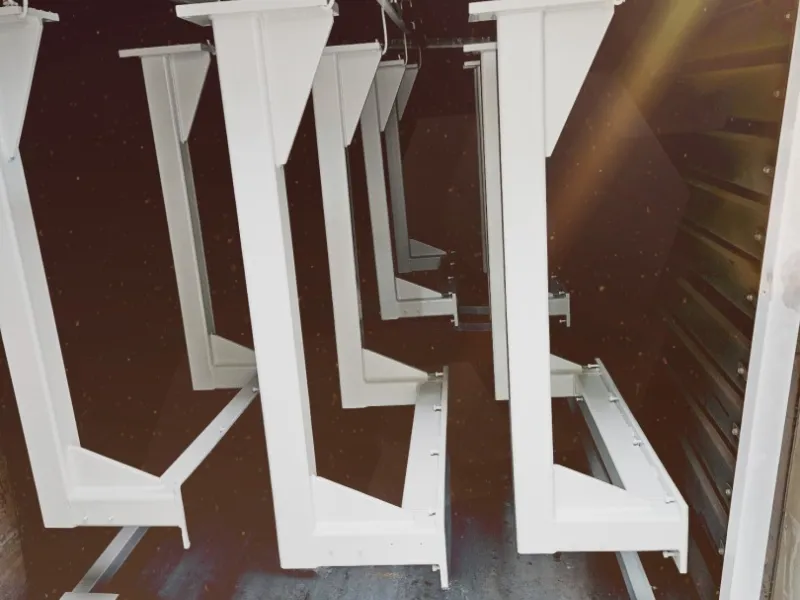

Powder Coating (Komaxit) – RAL Standard

A modern surface finishing method for final product appearance:

Wide selection of colors based on the RAL chart

High resistance to mechanical wear, UV radiation, and chemicals

Suitable for both indoor and outdoor use, including functional and decorative surfaces

Applied using a professional coating line, with strict control over spray quality, uniformity, and coating durability.

Laser Surface Cleaning

Advanced non-contact metal cleaning using laser technology:

Gentle, precise, and eco-friendly removal of layers (oxides, paint, grease, oxidation)

Ideal for sensitive surfaces, historical parts, or precision applications without damaging the base material

No abrasives or chemicals required – minimal waste, maximum environmental efficiency

Laser cleaning is a next-generation solution – suitable for surface restoration, renovation, or pre-welding preparation.

Reliability and Quality Under One Roof

All surface treatment processes are performed in strict compliance with quality standards and customer specifications. Each part undergoes final inspection, including visual checks and coating thickness measurement.

Your parts deserve more than just production — they deserve a professional final touch.

We ensure their durability, aesthetics, and long-term functionality in even the most demanding operational environments.