Modern sheet metal processing with TRUMPF technologies – a guarantee of precision and performance

Sheet metal processing is an integral part of our manufacturing activities. Thanks to our state-of-the-art technological infrastructure equipped with high-performance CNC machines from TRUMPF, we ensure fast, flexible, and highly precise production of parts that meet the most demanding customer requirements.

These technologies are among the most advanced solutions in sheet metal fabrication and provide a significant competitive advantage, especially in areas such as:

Automation of manufacturing processes,

Repeatable precision and quality stability,

Waste minimization and optimization of production costs.

Our key technological capabilities in sheet metal processing include:

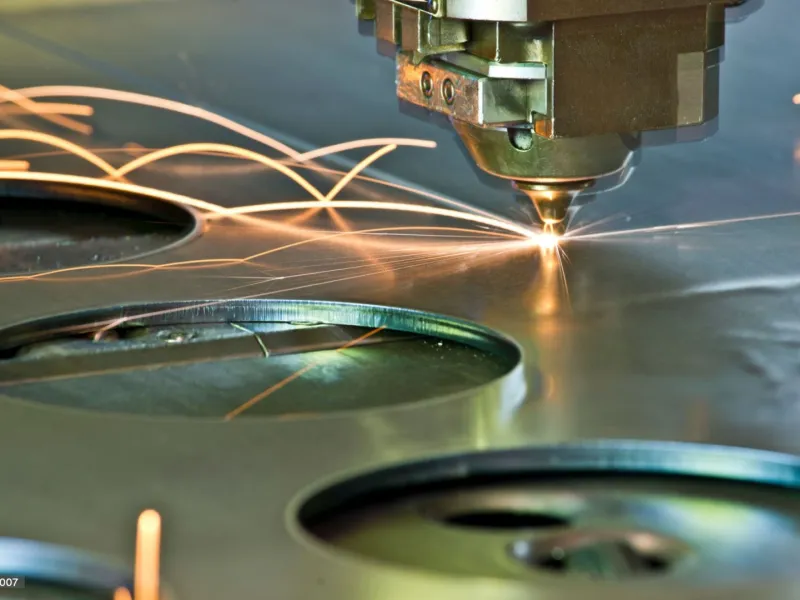

1. CNC Fiber Laser Cutting – TRUMPF TruLaser

High-performance CNC laser workstation using fiber laser technology designed for fast and precise cutting of steel, stainless steel, aluminum, and other metals.

Precise cuts even on complex geometries

Minimal thermal deformation of material

High speed and energy efficiency

Ideal for single-piece, small-batch, and serial production

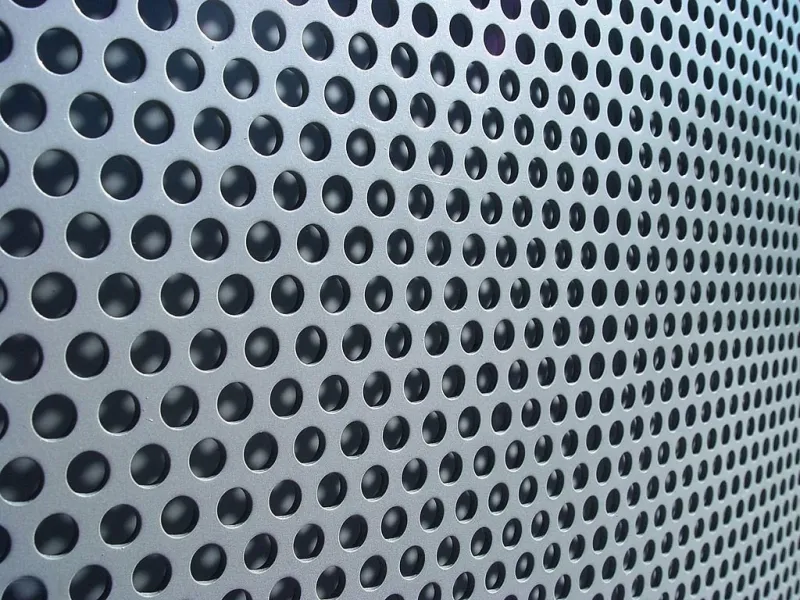

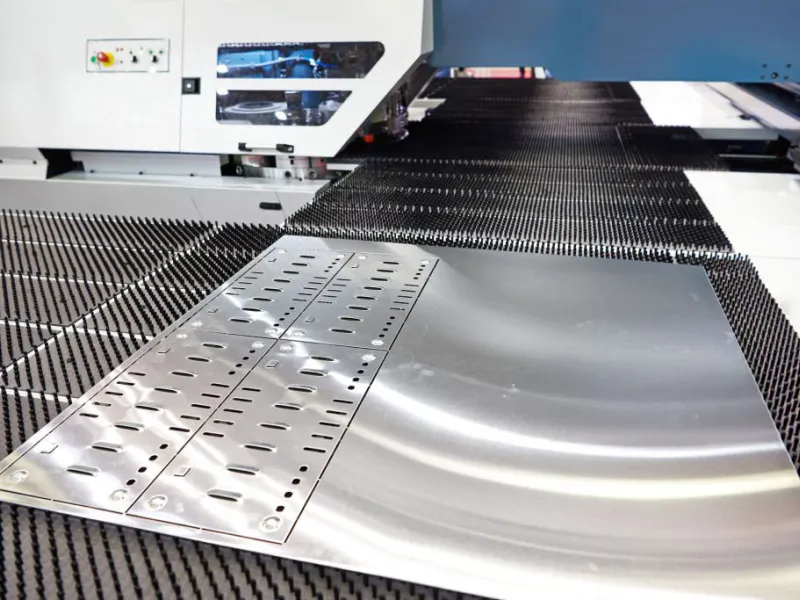

2. CNC Punching – TRUMPF TruMatic

CNC punching center enables fast and accurate shaping of sheet metal parts using tools with various profiles. The punching machine is perfect for producing perforated, shaped, or structured sheets.

Automated positioning and tool changing

Capability for embossing, threading, and marking

High productivity in repetitive manufacturing

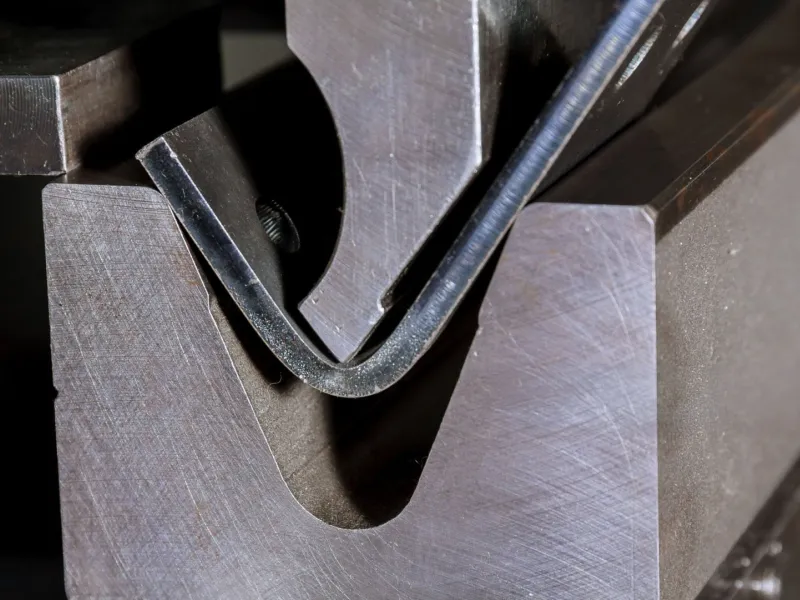

3. CNC Bending – TRUMPF TruBend

Precise CNC press brakes with controlled stop systems ensure consistent and repeatable bends on sheet metal parts of varying thicknesses.

High bending accuracy with minimal deviation

Quick setup and flexibility for different part geometries

Efficient processing of both small and large series

Comprehensive service – from design to finished product

By combining state-of-the-art TRUMPF technologies with our experienced team of engineers and machine operators, we provide a complete delivery of sheet metal components – from technical documentation processing to product finalization, surface treatment, and quality control.

Our customers value:

Short lead times thanks to efficient production planning

High-quality part processing, including dimensional precision and visual finish

Reliability and adherence to technical specifications for every order

Flexibility in both small and large batch production, including prototyping

Customer Value Proposition

Our investment in modern TRUMPF technologies is more than just a technological upgrade — it’s a strategic business tool. It enables us to:

Shorten the development and production time of components

Eliminate manufacturing inaccuracies and the need for rework

Quickly adapt to changes in customer requirements

Guarantee consistent quality, even in long-term and high-volume production runs

Your production, our precision.

With our TRUMPF technologies, you gain more than just metal processing – you gain a reliable partner for every stage of the production cycle.

Count on the precision of TRUMPF technologies and expert execution of every detail.

We process your components quickly, accurately, and with the highest quality – from cutting to final bending.